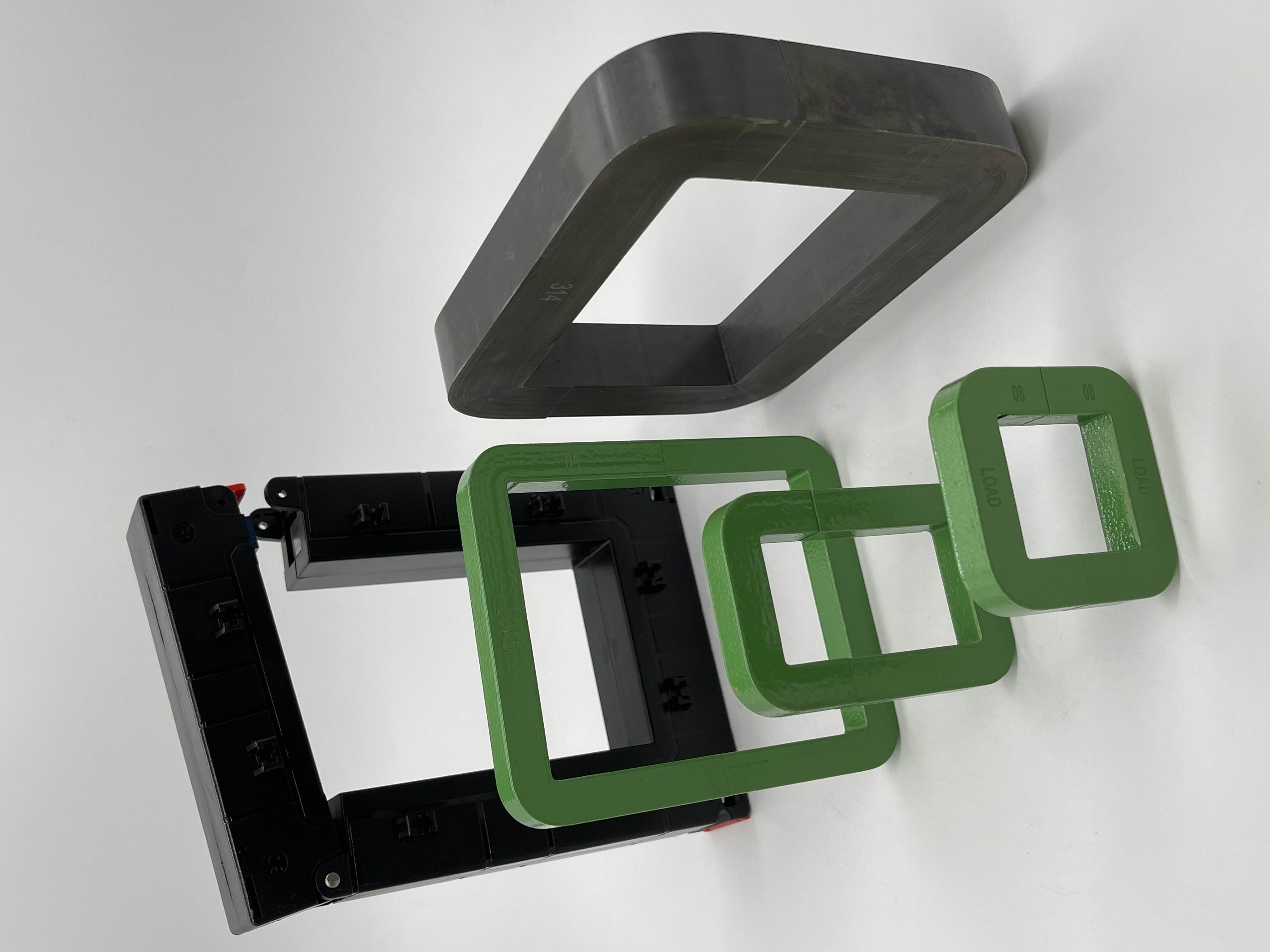

Transmart Silicon Steel Current Transformer Core

Silicon Steel Current Transformer Core has good magnetic permeability, low cost, mature manufacturing processes, and is widely used in current transformers. Low magnetic saturation induction strength, and they have higher losses at high frequency.

The shape of the silicon steel Current Transformer core can be rectangular or toroidal, with or without cutting, depending on the specific technical design and requirements.

Please visit our website for further information about our company.

Homepage: www.transmart.net

FOLLOW ME:

Check my website: https://www.transmartcore.com

Facebook: https://www.facebook.com/Transmart.Ind.Ltd

Youtube: https://www.youtube.com/@TransmartIndustrialLtd

LinkedIn: https://www.linkedin.com/company/transmart-industrial-limited/

Instagram: https://www.instagram.com/transmart307/

Pinterest: https://www.pinterest.com/transmart307/

X(Twitter): https://x.com/TRANSMART307

Tiktok: https://www.tiktok.com/@tst180307

Contact us today to learn more.

Email: sales@transmart.net

Whatsapp: +86 136 2868 9494

Silicon steel transformer cores are crucial components in electrical transformers, designed to improve their efficiency and performance. Here's a quick overview:

What is Silicon Steel?

Silicon steel, also known as electrical steel or silicon iron, is a type of steel alloy with a high silicon content (typically 1-4%). The addition of silicon enhances the steel's magnetic properties, which is essential for transformer cores.

Why Use Silicon Steel for Transformer Cores?

Magnetic Properties: Silicon steel has high magnetic permeability and low core loss, which means it can efficiently conduct magnetic flux while minimizing energy losses.

Reduced Eddy Currents: The silicon content increases the electrical resistivity of the steel, reducing the eddy currents that can cause energy loss and heating.

Improved Efficiency: Because of its low core loss and reduced eddy currents, transformers made with silicon steel are more energy-efficient, leading to lower operational costs.

Types of Silicon Steel

Grain-Oriented Silicon Steel: This type is specially processed to have a preferred crystallographic orientation, which greatly enhances its magnetic properties along the grain direction. It is commonly used in transformer cores for its superior performance.

Non-Grain-Oriented Silicon Steel: This steel is used where uniform magnetic properties are needed in all directions, but it’s less efficient compared to grain-oriented steel for transformer cores.

Manufacturing and Design Considerations

Lamination: Silicon steel sheets are typically manufactured in thin laminations to reduce eddy currents. These laminations are then stacked to form the core of the transformer.

Insulation: The laminations are often coated with an insulating layer to further reduce eddy currents and prevent short circuits between the sheets.

Core Shape: The shape and design of the transformer core, including whether it is a toroidal, shell, or core-type transformer, can affect the overall efficiency and performance.

Due to their high magnetic permeability and low cost, silicon steel CT CORES are suitable for mass-produced current transformer products. The thermal stability of silicon steel CT CORES is excellent, allowing them to withstand high temperatures, and their low coefficient of thermal expansion maintains stability in shape and size even at high temperatures. This makes silicon steel CT CORES suitable for use in many high-temperature environments, such as transformers, motors, and other applications where they are widely employed.

Applications

Silicon steel transformer cores are used in various types of transformers, including:

Power Transformers: For large-scale power distribution.

Distribution Transformers: For local voltage regulation.

Instrument Transformers: For measurement and protection.

In summary, silicon steel is chosen for transformer cores due to its excellent magnetic properties, which enhance the transformer's efficiency and performance while reducing energy losses.

Company Advantages

20 years experiences in magnetic cores manufacturing and exporting.

Various types magnetic materials available: Silion Steels, Nanocrystalline ribbon, Amorphous Ribbon, Mumetal