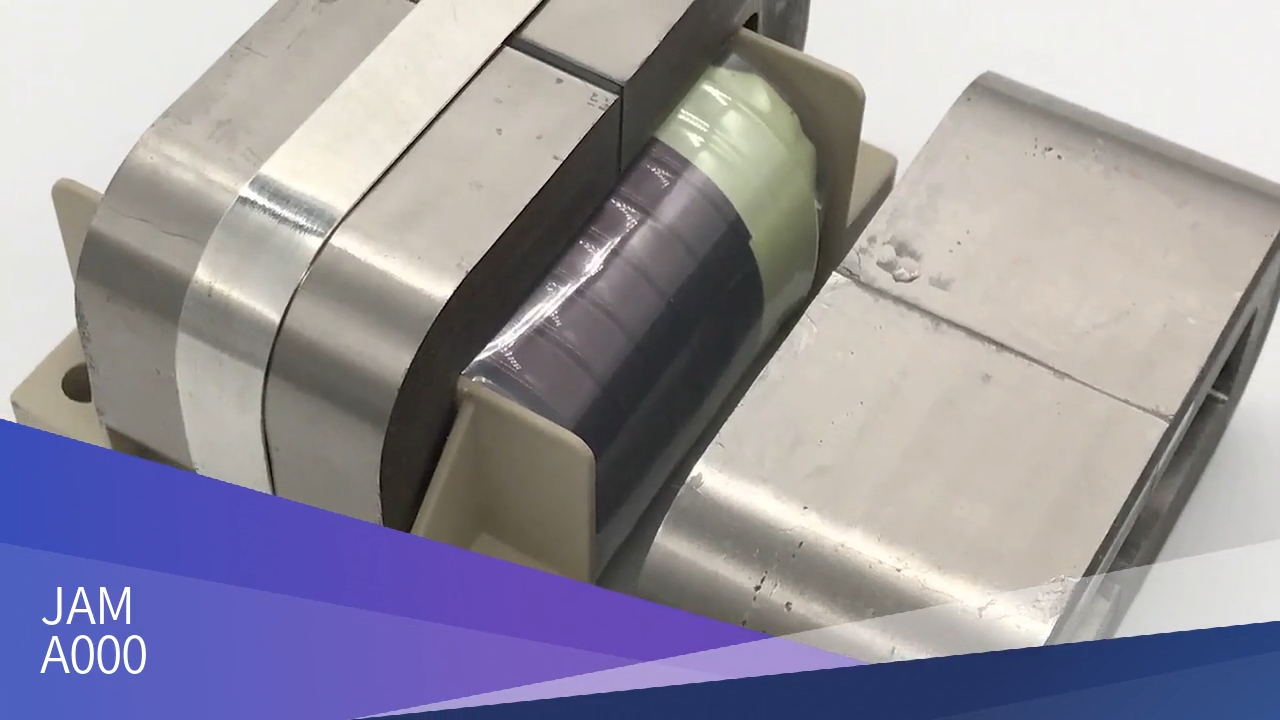

Custom Amorphous C-core Amorphous Magnetic Core Material

The amorphous C core is suitable for high power applications, easy to install, and easy to wind copper wire. It has high saturation flux density and low core loss. It is widely used in solar inverter filters, medium frequency transformers, output inductors, and PFCs.

Amorphous C-core is in high demands among the customers across the country. Our experienced team pays much more attention to the crafts design of . The Amorphous core can last for a long time. It is built with an intelligent circuit which can provide protection from overload protection or electrical leakage.

What Is An Amorphous Core?

The amorphous core is a type of magnetic core material that lacks a well-defined crystalline structure, differentiating it from traditional ferromagnetic cores typically used in transformers and inductors. Characterized by its non-uniform atomic arrangement, the amorphous core exhibits enhanced magnetic properties due to reduced energy loss during the magnetization process. This unique characteristic arises because the disordered nature of the atoms minimizes eddy currents and hysteresis losses—a significant advantage in applications requiring efficient operation, such as power supplies and electrical grid components. The production of amorphous cores involves rapid cooling techniques that prevent crystallization, resulting in materials like metallic glasses or soft magnetic alloys, which can significantly improve performance metrics in terms of energy efficiency and operational stability at various frequencies. Their remarkable ability to maintain low coercivity levels enables devices utilizing an amorphous core to operate with greater responsiveness and reliability under changing load conditions.

What Is The Difference Between Amorphous Core And Ferrite Core?

The distinction between an amorphous core and a ferrite core lies primarily in their material structures and magnetic properties, significant for various applications in electrical engineering. An amorphous core is crafted from metallic glass, characterized by its non-crystalline structure that results in low energy loss due to reduced magnetostriction and improved magnetic permeability. This unique arrangement enables better performance at higher frequencies compared to traditional materials. In contrast, ferrite cores are ceramic compounds composed of iron oxide mixed with additional metal oxides; they exhibit high electrical resistivity which minimizes eddy current losses but may come with limitations in terms of saturation flux density at elevated temperatures or frequencies. Consequently, while both types are utilized in transformers and inductors—targeting efficiency within electromagnetic devices—the amorphous core stands out for its optimal performance when managing hysteresis losses, making it a preferred choice for modern energy-efficient designs.